View All Recent Articles. Mechanical behavior of additive manufactured, powder-bed laser-fused materials Todd M. Long Effect of heat treatment on the microstructure and mechanical properties of Inconel processed by selective laser melting E. Influence of the prior athermal martensite on the mechanical response of advanced bainitic steel A. Investigation of short-term creep deformation mechanisms in MarBN steel at elevated temperatures A. Creep strength and minimum strain rate estimation from Small Punch Creep tests S. A in the last 90 days.

Most Cited Articles The most cited articles published since , extracted from Scopus. The latest Mendeley datasets for Materials Science and Engineering: Special issues published in Materials Science and Engineering: The Plum Print next to each article shows the relative activity in each of these categories of metrics: Captures, Mentions, Social Media and Citations. Go here to learn more about PlumX Metrics.

It has experienced steady and strong growth over its history, with many companies investing large amounts of money into developing new products. Biomaterials science encompasses elements of medicine , biology , chemistry , tissue engineering , and materials science. Biomaterials can be derived either from nature or synthesized in a laboratory using a variety of chemical approaches using metallic components, polymers , bioceramics , or composite materials.

Such functions may be benign, like being used for a heart valve , or may be bioactive with a more interactive functionality such as hydroxylapatite coated hip implants. Biomaterials are also used every day in dental applications, surgery, and drug delivery.

Materials science

For example, a construct with impregnated pharmaceutical products can be placed into the body, which permits the prolonged release of a drug over an extended period of time. A biomaterial may also be an autograft , allograft or xenograft used as an organ transplant material. Semiconductors, metals, and ceramics are used today to form highly complex systems, such as integrated electronic circuits, optoelectronic devices, and magnetic and optical mass storage media. These materials form the basis of our modern computing world, and hence research into these materials is of vital importance.

Semiconductors are a traditional example of these types of materials. They are materials that have properties that are intermediate between conductors and insulators. Their electrical conductivities are very sensitive to impurity concentrations, and this allows for the use of doping to achieve desirable electronic properties.

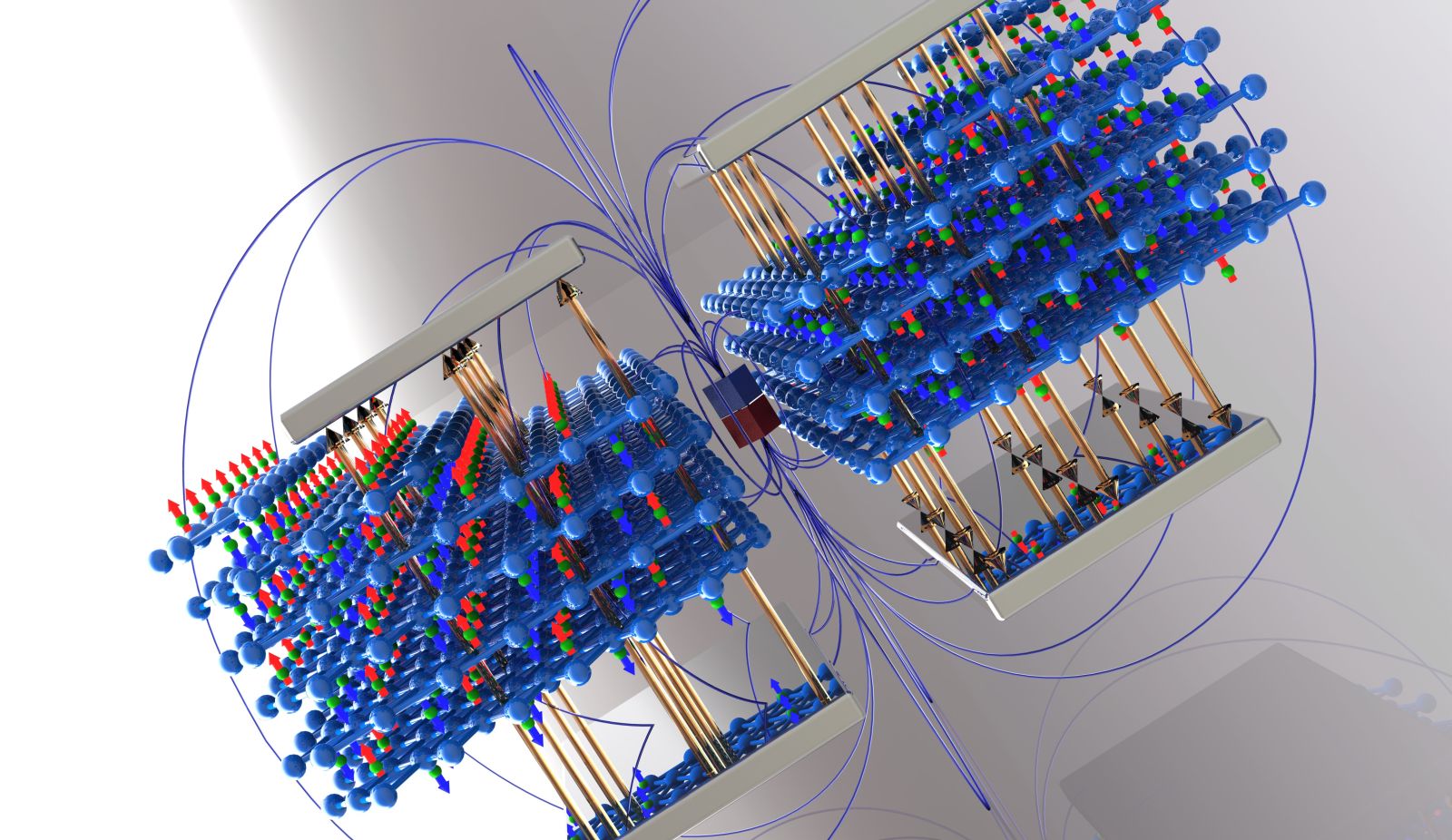

Hence, semiconductors form the basis of the traditional computer. This field also includes new areas of research such as superconducting materials, spintronics , metamaterials , etc. The study of these materials involves knowledge of materials science and solid-state physics or condensed matter physics. With the increase in computing power, simulating the behavior of materials has become possible. This enables materials scientists to discover properties of materials formerly unknown, as well as to design new materials.

Up until now, new materials were found by time-consuming trial and error processes. But, now it is hoped that computational methods could drastically reduce that time, and allow tailoring materials properties. This involves simulating materials at all length scales, using methods such as density functional theory , molecular dynamics , etc.

Radical materials advances can drive the creation of new products or even new industries, but stable industries also employ materials scientists to make incremental improvements and troubleshoot issues with currently used materials. Industrial applications of materials science include materials design, cost-benefit tradeoffs in industrial production of materials, processing methods casting , rolling , welding , ion implantation , crystal growth , thin-film deposition , sintering , glassblowing , etc.

Besides material characterization, the material scientist or engineer also deals with extracting materials and converting them into useful forms. Thus ingot casting, foundry methods, blast furnace extraction, and electrolytic extraction are all part of the required knowledge of a materials engineer. Often the presence, absence, or variation of minute quantities of secondary elements and compounds in a bulk material will greatly affect the final properties of the materials produced.

Thus, the extracting and purifying methods used to extract iron in a blast furnace can affect the quality of steel that is produced. Another application of material science is the structures of ceramics and glass typically associated with the most brittle materials.

Bonding in ceramics and glasses uses covalent and ionic-covalent types with SiO 2 silica or sand as a fundamental building block. Ceramics are as soft as clay or as hard as stone and concrete. Usually, they are crystalline in form. Most glasses contain a metal oxide fused with silica. At high temperatures used to prepare glass, the material is a viscous liquid.

The structure of glass forms into an amorphous state upon cooling. Windowpanes and eyeglasses are important examples. Fibers of glass are also available.

Materials Science and Engineering: A

Scratch resistant Corning Gorilla Glass is a well-known example of the application of materials science to drastically improve the properties of common components. Diamond and carbon in its graphite form are considered to be ceramics. Engineering ceramics are known for their stiffness and stability under high temperatures, compression and electrical stress. Alumina, silicon carbide , and tungsten carbide are made from a fine powder of their constituents in a process of sintering with a binder.

Hot pressing provides higher density material. Chemical vapor deposition can place a film of a ceramic on another material. Cermets are ceramic particles containing some metals. The wear resistance of tools is derived from cemented carbides with the metal phase of cobalt and nickel typically added to modify properties.

Filaments are commonly used for reinforcement in composite materials. Another application of materials science in industry is making composite materials. These are structured materials composed of two or more macroscopic phases. Applications range from structural elements such as steel-reinforced concrete, to the thermal insulating tiles which play a key and integral role in NASA's Space Shuttle thermal protection system which is used to protect the surface of the shuttle from the heat of re-entry into the Earth's atmosphere.

RCC is a laminated composite material made from graphite rayon cloth and impregnated with a phenolic resin. After curing at high temperature in an autoclave, the laminate is pyrolized to convert the resin to carbon, impregnated with furfural alcohol in a vacuum chamber, and cured-pyrolized to convert the furfural alcohol to carbon. To provide oxidation resistance for reuse ability, the outer layers of the RCC are converted to silicon carbide. Other examples can be seen in the "plastic" casings of television sets, cell-phones and so on.

These plastic casings are usually a composite material made up of a thermoplastic matrix such as acrylonitrile butadiene styrene ABS in which calcium carbonate chalk, talc , glass fibers or carbon fibers have been added for added strength, bulk, or electrostatic dispersion. These additions may be termed reinforcing fibers, or dispersants, depending on their purpose.

Polymers are chemical compounds made up of a large number of identical components linked together like chains. They are an important part of materials science. Polymers are the raw materials the resins used to make what are commonly called plastics and rubber. Plastics and rubber are really the final product, created after one or more polymers or additives have been added to a resin during processing, which is then shaped into a final form. Plastics which have been around, and which are in current widespread use, include polyethylene , polypropylene , polyvinyl chloride PVC , polystyrene , nylons , polyesters , acrylics , polyurethanes , and polycarbonates and also rubbers which have been around are natural rubber, styrene-butadiene rubber, chloroprene , and butadiene rubber.

Plastics are generally classified as commodity , specialty and engineering plastics. Polyvinyl chloride PVC is widely used, inexpensive, and annual production quantities are large. It lends itself to a vast array of applications, from artificial leather to electrical insulation and cabling, packaging , and containers. Its fabrication and processing are simple and well-established. The versatility of PVC is due to the wide range of plasticisers and other additives that it accepts. The term "additives" in polymer science refers to the chemicals and compounds added to the polymer base to modify its material properties.

Such plastics are valued for their superior strengths and other special material properties. They are usually not used for disposable applications, unlike commodity plastics. Specialty plastics are materials with unique characteristics, such as ultra-high strength, electrical conductivity, electro-fluorescence, high thermal stability, etc. The dividing lines between the various types of plastics is not based on material but rather on their properties and applications.

For example, polyethylene PE is a cheap, low friction polymer commonly used to make disposable bags for shopping and trash, and is considered a commodity plastic, whereas medium-density polyethylene MDPE is used for underground gas and water pipes, and another variety called ultra-high-molecular-weight polyethylene UHMWPE is an engineering plastic which is used extensively as the glide rails for industrial equipment and the low-friction socket in implanted hip joints.

The study of metal alloys is a significant part of materials science. Of all the metallic alloys in use today, the alloys of iron steel , stainless steel , cast iron , tool steel , alloy steels make up the largest proportion both by quantity and commercial value.

Iron alloyed with various proportions of carbon gives low, mid and high carbon steels. An iron-carbon alloy is only considered steel if the carbon level is between 0. For the steels, the hardness and tensile strength of the steel is related to the amount of carbon present, with increasing carbon levels also leading to lower ductility and toughness. Heat treatment processes such as quenching and tempering can significantly change these properties, however. Cast Iron is defined as an iron—carbon alloy with more than 2. Nickel and Molybdenum are typically also found in stainless steels.

Other significant metallic alloys are those of aluminium , titanium , copper and magnesium. Copper alloys have been known for a long time since the Bronze Age , while the alloys of the other three metals have been relatively recently developed. Due to the chemical reactivity of these metals, the electrolytic extraction processes required were only developed relatively recently. The alloys of aluminium, titanium and magnesium are also known and valued for their high strength-to-weight ratios and, in the case of magnesium, their ability to provide electromagnetic shielding.

These materials are ideal for situations where high strength-to-weight ratios are more important than bulk cost, such as in the aerospace industry and certain automotive engineering applications. The study of semiconductors is a significant part of materials science. A semiconductor is a material that has a resistivity between a metal and insulator. Its electronic properties can be greatly altered through intentionally introducing impurities or doping. From these semiconductor materials, things such as diodes , transistors , light-emitting diodes LEDs , and analog and digital electric circuits can be built, making them materials of interest in industry.

- Hipsters. Un manual ilustrado (Spanish Edition).

- Page navigation.

- Engineering Materials Science | ScienceDirect.

- What is materials science? - Materials Science and Engineering - The University of Sheffield.

- Navigation menu.

- Tropical Arms (The Kristen Maroney Mysteries Book 5).

Semiconductor devices have replaced thermionic devices vacuum tubes in most applications. Semiconductor devices are manufactured both as single discrete devices and as integrated circuits ICs , which consist of a number—from a few to millions—of devices manufactured and interconnected on a single semiconductor substrate. Of all the semiconductors in use today, silicon makes up the largest portion both by quantity and commercial value. Joining the Institute of Materials, Minerals and Mining IOM3 gives you access to information, training and networking opportunities, as well as competitions and awards.

A discounted rate is applied for students. Search for placements and find out more about work experience and internships. There are also opportunities in teaching and research, finance e. Developments in the field of nanotechnology and in the use of biomedical materials, high-performance textiles, composites and sustainable materials, are also creating more job opportunities. Find information on employers in engineering and manufacturing , energy and utilities , science and pharmaceuticals and other job sectors.

Materials Science and Engineering: A - Journal - Elsevier

You will gain a good understanding of scientific structures and will be able to choose modules that relate to your areas of interest. Studying for a materials science and engineering degree also provides you with a strong set of transferable skills valued by employers. Studying at postgraduate level MSc, MRes or PhD enables you to acquire specialist knowledge in a particular sector or material. For example, in offshore operations, the aerospace industry or working with composites or glass. Relevant courses of study are available across the UK and you can find information about accredited university courses from the IOM3.

You could also undertake additional training in appropriate software, such as Finite Element Analysis modelling. If you wish to move outside the materials field you could study for a professional qualification in law, finance or teaching. For more information on further study and to find a course that interests you, see Masters degrees and search postgraduate courses. Approximately two-thirds of materials science graduates are in employment six months after graduating.