I have experience with lean but it is my first time using a VSM for an information based process. Should this be seen as a defect or low quality? Additionally report making is a definite Push process in this organization, much of the data gathered during the day is not relevant to higher management but is still recorded and passed on. In a future state map I would like to show that only relevant data, like anomalies, are passed on. The reason for passing on would then approach a Pull process.

To this end, I want to classify irrelevant data as a defect or low quality. I feel like I should make a distinction between incomplete data and irrelevant data. Incomplete data is a defect that should not be passed down the line, but I think classifying irrelevant data as a defect might be too rash. I would like to know if you know of any examples of a VSM used in an information process and if you would be willing to share these? Anyway, thanks in advance for any help. A VSM can be tailored to meet your specific needs and you do not have to use a specific defined version.

Think about what you want to achieve with your map and how people may perceive what you say. Collecting and processing irrelevant data is a waste, maybe you can highlight how much waste is actually being produced in regards to time processing this information. Another way to consider it is to look at the processing time at each stage — what could it be on your future state map if the irrelevant data were removed?

You should also ask yourself why you cannot involve the people from the process in completing your map. In which case a simple process map may be more appropriate for what they want. Sometimes simple and easy to understand is far better than something that may be unfamiliar and overly complicated. The ideal state VSM is where you would like to get to if everything could be done perfectly. Often this is not achievable overnight as you would have to move entire factories around, change supplier relationships and a host of other things.

So each step change that you want to make would be represented by a future state map of where you want to get to with each project that you run.

So there may be several future state maps that you work towards before you reach your ideal. I have recently joined a confectionery industry and my first project is reduction of the existing workforce. The main driving force of the company is its manpower.

Can VSM help me in reducing my workforce without having considerable effect on quality? Can it by giving me tangible outcomes, comparing the present and proposed plan of action? Or some other method would be more fruitful? VSM on its own is not going to make a great reduction on the workforce. Most lean tools should use the workforce themselves to implement and you are not going to get much help if your aim is to get rid of the staff.

Value stream mapping

As a realist I do understand that at times a company will have to shed labor to survive and the use of simple process mapping and waste analysis can help you with this by identifying the non value adding steps in the process. For developing the VSM for a train , I identified 5 parts are essential Front, side, rear , cabin and roof. Each main part i. Now, when preparing a VSM for the main line, cycle time of the main part should be considered the assembly time of the main part to the train or the time taken to manufacture from the sub parts.

Please clarify me what to take as cycle time and also. Hi Sathwick, I will be honest I am not sure that I fully understand what exactly you are asking but I will try to answer as I think. The cycle time should be the main process flow if that is what you are designing a VSM to improve. As VSM for sub-assemblies will help you to improve the main flow also and identify if there are any issues that may impact the main line such as an inability to provide the volume that the main line requires or quality issues that may impact the main build.

Good quality, clear and concise information. I am starting to run VSM in an automotive supplier with two seperate customers who we supply to. One is approximately m from the plant, the other is miles. The two production lines are seperate and the flow runs in opposite direction eek. Should I map them seperately and essentially plan a transformation plan for each? I would map each line separately as they are distinct lines with different customers and I assume very different requirements.

Best of luck with your value stream map — let us know how well you get on and if you need any more help. In this particular case it is an implementation process of new transport routes from supplier to factory. My feeling is that the VSM methodology is more adapted to physical flows of material rather than desk flows. Transforming paper or electronic based information can still be considered a manufacturing process, it has an input, a transforming process and an output.

A Bit of History

So yes you can approach it in much the same way. As to buffers; how big is your in-tray on your desk? I led a team a while back that was looking at reducing the lead time taken for engineering changes that involved products and components that were already existing within the product line.

This was on vehicle seating so the changes could be as simple as swapping the style of arm rests, or the color of the material being used. The existing system went through several internal sign offs and departments and often took up to 13 weeks to make a simple change in the paperwork etc. After just a few weeks we demonstrated a new system; the management team picked a new design using existing components at random and we provide all of the updated drawings, assy instructions, quality paper work and the actual product in just one hour.

We used a very simple VSM to initially map the process and started chopping out everything that was there for the sake of bureaucracy and achieved no real value before looking at ways to to reduce processing and waiting times between processes. So yes a VSM can be used on any process. The real value on using a VSM however is in being able to visualize that future state that you wish to reach; and then getting there. I have been asked to make a VSM regarding the dispatch process from the factory of my firm. Starting from truck entering the plant to truck leaving the plant.

There are often idle times between some processes which is make difficult to calculate the cycle time of that process. Can it be like noting the time when actually the work is being performed and noting the time if a halt occurs in any situation then again noting the time when that particular work starts to calculate how much time the work was actualy performed as the cycle time.

What is Value Stream Mapping?

Is this practice fine or something else may be done. Regarding Takt time, as there is a variation in the number of trucks that are dispatched everyday so how may be the Takt time calculated. Kindly help me out. I am also a little confused as to what you are specifically asking. Hi, I would first like to thank and congratulate you for the good quality of the article and the important information given about VSM. As I said, every family of products passes through many units, each unit with its own Raw Materials and machines and performance.

Thank you very much for your interest. As with any VSM the answer is always going to be whatever gives you the information that you need to understand the process and visualize the improvements that you need to make. Think about what you actually want to know and draw your map accordingly. But always ensure that you have to hand the other information that you may need. Personally, without having a full idea of what you are mapping, I would probably start by selecting a single product or family and map that fully.

Select the one that is the biggest value to the business and use that as your starting point. Trying to do and show everything is often just too much. If you try to do everything at once then you are just going to bog yourself down in analysis and data gathering and will never start to get to the point of taking action.

If you want to have a more detailed discussion feel free to contact me directly. I really find this article very informative and helpful. I have heard about how to represent that ceremonies but I am not pretty sure how. If you could help me I appreciate.

When to do Value Stream Maps (and when not!) | tandjfoods.com

Excellent explanation of VSM. No one has ever explained it in such clear detail and why each step is important — even the sub-steps. This is, by far, the clearest explanation of VSM I have ever seen. I would like to ask about tips constructing vsm for non manufacturing. I hope you can share some tips. I am wondering how the VSM represents steps in the process that overlap?

By this I mean for example a laboratory-environment where samples are received in bulk but are processed in smaller batches. While sub-process 1 is still working on the received batch, sub-process 2 might start working on smaller batches that are available. How do you represent this in the VSM-drawing do you show overlap? Hi Alexander, Would be helpful to have a little more detail.

If you want feel free to contact me with what you have so far for your VSM through the contact page and I will see what advice I can offer you. I am currently working as an Intern in an Automotive supplier company. I am given a task to optimize the information flow between internal departments. I am really confused and helpless as for how to proceed further The support from the management is also not good.

Initially, after I collect the information flow between departments, I have a plan to draw a detailed VSM to visualize the material and Information flow for a particular Product. The current state Map will actually show how the information is being transferred in each step and will display the bottleneck of the information as well as material, with which we can plan and change the mode of data transfer. Hi Rammoghen, Without seeing how complex the information is that you have collected it can be hard to give a definitive answer to your question.

But from what you say a VSM could be one way to show where information is being held up if you show the workload that is at each stage in the process; maybe with a work in progress measure showing the number of documents with an average time for processing each. Be careful when measuring processing time, maybe it only takes a few seconds to sign a piece of paper but they will often sit there for days before being reviewed.

I would be inclined to take an average number of documents processed in a specific day to calculate a processing time. After the initial explosion and fall out things were soon improved. People were given responsibilities to approve work rather than sending multiple documents through many different departments and other issues. Best of luck with what you are doing. Thank you for the great explanation.

I was wondering how does the Change over time influences the Total Lead Time calculation. I am currently doing an internship in a transformer workshop. Where refurbishing of faulted transformers occurs. I have been handed an assignment to create a vsm for them. I would like to know how should i start and what kind of data i require. Either we will take the averages or will use the sum of all time consumed by all samples?

Whoa, whoa, hold your horses. Do you really want a consultant fiddling with your shop floor without understanding what is really going on? Giving the consultants time to understand the shop floor is a necessity for a successful lean project! If they make a value stream map on the side, it does not hurt.

Just remember that a value stream has a specific use but is not a tool to solve all problems. This also gives them a good understanding of the shop floor, possibly even more than a value stream map would. Although I imagine this may not be too popular with some consultants. The value stream map can give you a graphic representation of the information and material flow.

This in turn can help you with both understanding and improving your shop floor organization. As with all lean improvement projects, you should first have a problem that you want to fix! Then, depending on the problem, you collect data, make different analyses, and use appropriate lean tools to improve your problem.

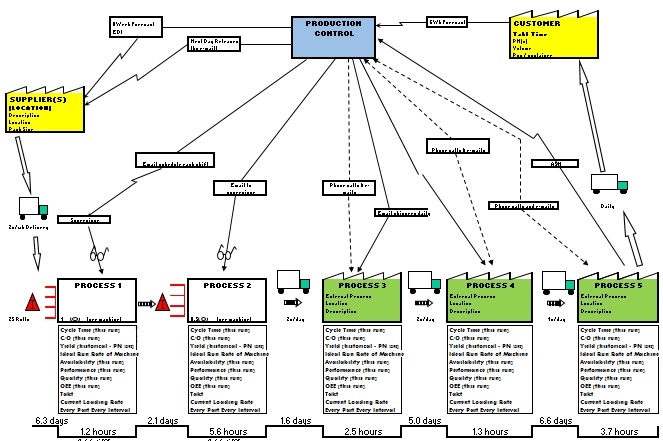

A tool by itself is not a solution. A value stream map is a flow layout of the material and information flow. As such, it can help you visualize and understand the material and information flow. This can be done for the current state also called value stream analysis or VSA and also for the future desired state also called value stream design or VSD. As such, value stream maps can help you with understanding the flow of information and material.

It can help you to see problems and inconsistencies. Common issues where value stream mapping is often useful are, for example:. Please keep in mind that depending on the exact problem you try to solve, the maps can look differently. For example, if I want to determine the lead times, I count material. For other problems, a value stream map may or may not help, depending on the details of your problem. Below are some examples of when a value stream map can be done somewhere during the improvement, but this is not necessarily clear at the beginning of the project.

Value stream mapping is a useful tool. However, it is not a catch-all multi-purpose tool that solves all of your problem. Any issue not connected to the material or information flow is unlikely to benefit from a value stream map. Similarly, systems without a highly linear information and material flow usually do not benefit from drawing a value stream map either for this, swim lane diagrams are more useful.

Common examples of when a value stream map usually makes no sense are, for example:. Again, get the right tools for the problem, not the other way around! Value stream maps have a lot of good uses, but they are not for every problem. Do a value stream map if you think it can help your particular problem, but not just because someone tells you to do it.

As always, I am looking forward for comments here or through social media. Now go out and organize your Industry! VSM for me is , perhaps , the most powerful lean tool to achieve a cross-functional organization , i. VSM does have some limitations. It does not work well with job shops or most offices, or generally less structured flows of information and materials.

More on this topic coming up in the next few weeks. But it is a great tool if applied correctly. No cookie-cutter solutions to problems that do not exist. Good thinking, good writing. This blog is quickly becoming a VA part of my routines, for which I make time.

I just wanted to make one more comment on the advantages of using a VSM. In my experience it is a good tool to get management support and alignement on what to work on. So by getting management to do a VSM workshop you get them onto the shopfloor and they will see the problems by themselfes. Hi Johann, that sounds good.

I would like to emphasize that in CI program, the team member participation is the main activity. When does VSM come in then? VSM is a very effective tool for analysis and confirmation of actual situations for possible countermeasures.

What is Value Stream Mapping (VSM)

When using the cause and effect diagram, VSM data provides the cause and effect for quality, cost and delivery problems. With cause and effect at hand, we identify the detail of measures and the expected results. Therefore, VSM provides details, values, and the almost complete situation of the particular subject problem and countermeasure directions. It is knowledge then! Knowledge that provide members a good understanding of the analytical process and details.

And when members understand, they are motivated and encourage to participate and share each of their ideas. Sharing cannot occur if members are not motivated with knowledge. It was mentioned how some companies hire consultants who provide directions and often push the team to participate with or without confidence by virtue of their own knowledge shared by internal trainors or facilitators. VSM is a very powerful tool for analysis, for knowledge and for reference.

One most difficult factor in terminating a problem in a business environment such as manufacturing is recurrence and unfinished measures. A well done VSM can increase the achievement factor. Hi Danilo, thanks for the input. I agree, almost everything in lean is about people. VSM gets people on the shop floor to understand the situation and to see if it is better afterwards.

I believe the best solution in application of lean starts with distilling Managements vision of what they hope to achieve. Specifically, because often management does not have a vision but only that they need to do lean. Then take this vision to the people and seek the low hanging fruit. This can be done one on one or in a team setting explaining the merits of lean with examples of successes in lean applications.

Also this is the time to share the vision our management has for our lean mission. Often just having developed rough numbers for peoples waste and just listening to them will provide more projects than can be facilitated so with your rough numbers apply Pareto and look for the biggest bang for the buck. Communication is another hotly missed tool in the application of lean sharing of best practices. Management involvement is often lacking in the west, and communication across departments is also often limited.

Thank you for the extensive comment. In my experience VSM is useful in seeing the big picture so as to avoid working in isolation on shop floor projects that may actually conflict with each other. Thanks for very interesting article. I support what you said and I agree that VSM very difficult to use for job shop. I have another question. What do you recommend to use for job shop instead?

Which tool do you believe is the best? I usually approach it using a matrix of parts and processes, although this also has some problems with loops and alternatives. Another option is to — sort of — force a VSM on it if you have a product or product group that is more common than others. Actually, identifying the target condition should be one of the primary uses of the VSM. So, you may not know the problem you want to address when you begin your VSM. Not a random haphazard one. The kaizen bursts on the FSVSM are what point you to the strategic improvements that need to be made in order to achieve the target.

Hi RMiller, in my view VSM is good at identifying only a few type of problems connected to the information and material flow. Hence, i do not use VSM to find problems in general.